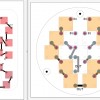

I get an idea, and I usually just run when it. Especially when the idea excites me creatively. A hour or so at Illustrator and I’ve got the planned mask laid out for the copper clad circuit board etching. The black lines with the +/- on them will be printed out on transparency film and hopefully I will get good results. The kit I have is a “positive mask” style, meaning I will have to reverse the image to properly mask off the copper.

New to the site?

Check out the first month (May 2011) in the Post Archives below and work your way forward to get caught up on the project.Follow on Facebook

Follow on Instagram

Site Search

Post Categories

Post Archives

- March 2023

- January 2023

- June 2021

- June 2020

- April 2020

- February 2020

- September 2019

- January 2019

- December 2018

- October 2018

- July 2018

- March 2018

- January 2018

- October 2017

- August 2017

- April 2017

- December 2016

- September 2016

- August 2016

- May 2016

- April 2016

- February 2016

- September 2015

- February 2015

- December 2014

- August 2014

- May 2014

- March 2014

- February 2014

- October 2013

- September 2013

- August 2013

- July 2013

- June 2013

- April 2013

- November 2012

- August 2012

- July 2012

- June 2012

- May 2012

- April 2012

- March 2012

- February 2012

- January 2012

- December 2011

- November 2011

- October 2011

- September 2011

- August 2011

- July 2011

- June 2011

- May 2011