One of the things that I have to tackle with the MogRod is the upgraded wiring. Even with much of the car still a ways off, I wanted to do *something* to move forward on the project. I’d already researched into a lot of the modular bits, and started ordering those.

A while back I picked up a Directed Electronics “Nite-Lite” setup, which will give me the automatic headlight functions most modern cars have. This is a feature I absolutely love on all our other modern cars, and is a must-have in my opinion on any resto-mod project.

I just recently ordered Painless Performance Wiring’s H4 halogen headlight conversion kit, which will be modified into a ‘direct plug-in’ setup. I also ordered their turn signal kit with the LED lighting module. I’ll get into that second bit in a moment…

Another thing I’ve been thinking about was a keyless ignition setup. I wanted a more modern approach to starting the car, and not having a set of keys definitely is a step in that direction. After browsing around at a number of different kits available on the market, I’ve decided upon Digital Guard Dawg’s “2Go Keyless” system. The two key points that made me decide on them (besides the all-around best price) was that they were the only ones that offered a stand-alone “ignition only” system, and were the only ones whose push button setup made the most sense. All the other manufacturers had some stupid “push the button 3 times” or some similar kind of setup. I wanted pretty much what my father has on his XLR – step on the brake (and the clutch for neutral-safety in the MogRod’s case) and put the start button to go. This system I will be ordering in the near future when some other bills and whatnot are cleared up.

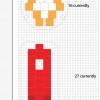

Now, back to the LED signals… I pulled out the replacement indicator and brake light fixures I ordered a while back, and quickly realized I didn’t care for how the factory bulbs were arranged. Also, I realized that there was no real place for a reverse light to go on the car. I began scheming, and after much measuring and designing, came up with the plans for fully LED brake, running, reverse, and signal lights. The one change to ‘factory appearance’ I will be doing is swapping out the red lenses on the rear signal housings for clear ones similar to the fronts. This way, I’ll be able to use what would be the ‘running lights’ up front as reverse lights in the rear. You can see in the images below the planned layout for the led lights, the darker reds being the night time ‘rear running lights’.

I’ve placed an order for a batch of the LED’s and they should be showing up in a week or so. In the mean time, I got busy with getting the actual boards cut out. I stayed after work today and laid out the cut paths for the CNC router to go with, and within half an hour had plenty of custom cut boards to spare. I will be attempting to fit into my schedule a soldering class at the local Tech Shop, since even though I have soldering experience, I’d rather be certain of what I’m doing than damage anything. I certainly have to say the ease with which I custom-cut the PCB board has me eager to come up with some other projects to do with the material.

- Test run

- Cutting begins

- Cutting the mounting holes

- First viewing

- Cutting continues

- And I have a full selection of light boards!

- The planned layout.

2 Responses to So I was feeling a bit board…